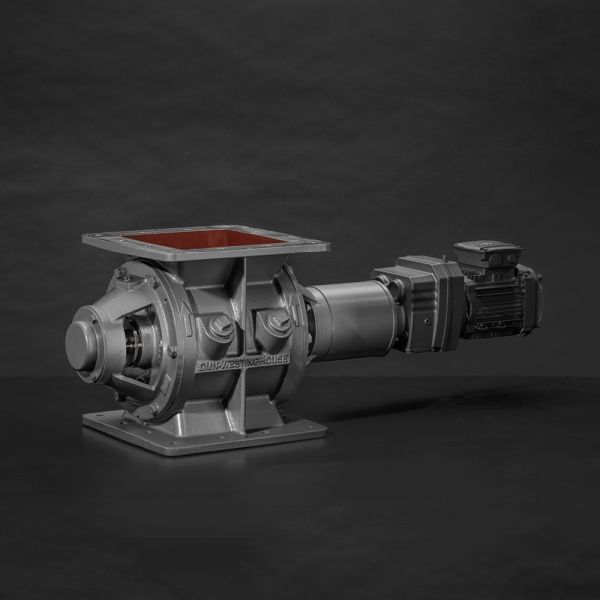

Air Locks

Rotary valves (Air locks) serve as crucial components in dry bulk handling systems, controlling material flow, maintaining system pressure, ensuring consistent feeding, and enables product metering.

AL/AXL

All-round rotary valve for metering and conveying powders and granules

The AL and AXL rotary valves, adept in metering and conveying powdersand granules, feature modular designs for various configurations. With its larger inlet, AXL excels in managing products with challenging

flow properties. These stainless-steel rotary valves are ideal for food and pharmaceutical

sectors, which meet USDA Dairy and EC1935/2004 standards, offering easy disassembly and high hygiene.

MZC models simplify rotor and end cover removal by adding rails, while the adaptable AML variant transitions between round and square interfaces, enhancing versatility in system design.

AML

All-round rotary valve with one round and one square flange

The AML rotary valves are suitable for many applications in the metering and pneumatic conveying of products in powder and granular form. These valves can also act as a transition piece from round to square and vice versa. The AML rotary valve range also includes USDA Dairy-accepted models and versions compliant with the EC1935/2004 directive for sanitary use in the food and pharmaceutical industry. These stainless-steel rotary valves are easily detachable and meet the highest hygienic standard

USAL

All-round rotary valve with two square flanges

The USAL rotary valves have been designed for many applications in the metering and pneumatic conveying of products in powder and granular form. The USAL has square inlet/outlet flanges. It has an enlarged inlet, Designed for applications where inlet size is more important than capacity, or for handling products that flow poorly.

SAL

Heavy-duty sanitary rotary valve

The SAL rotary valve is a low-capacity rotary valve with a highly polished surface inside and outside. The SAL is suitable for metering applications where very high hygienic standards, and ease of operation and cleaning are required. The complete rotary valve can be dismantled for inspection and cleaned in minutes, thus reducing eventual downtime and production loss.

GL

Granular rotary valve for gravity feed or pneumatic conveying

The GL rotary valves are specially designed for gravity feeding and pneumatically conveying granular products. The configuration of the body and rotor have been developed specifically to minimize product degradation while retaining the best possible pocket-filling efficiency.

NR347

Exact fit for replacing your Niro rotary valve

Thinking of replacing your existing Niro rotary valves? Our NR (Niro Replacement) rotary valve matches the outer dimensions of the existing Niro rotary valve in your system, Meaning they are exactly fit for most of the time.

Our replacement rotary valves are based on the AL250 model, and made of stainless steel.

They meet all hygiene and safety standards, ensuring their future-proof value.

BL/BXL/BXXL

Precision metering and pneumatically conveying with a modular design

Engineered for precision in metering and pneumatic conveying, Our BL, BXL, and BXXL rotary valves easily handle powder and granular products. Their modular design allows for diverse configurations. The BXL rotary valve, with its enlarged inlet, excels in applications demanding larger inlets or processing products that do not flow smoothly, With the BXXL offering an even greater inlet size. Crafted from cast iron, Stainless steel, or aluminum, these rotary valves are quickly detachable, maintaining the highest hygienic standards. The BL, BXL and BXXL models also come in MZC versions, featuring supportive rails for effortless end cover and rotor removal without damaging the housing.

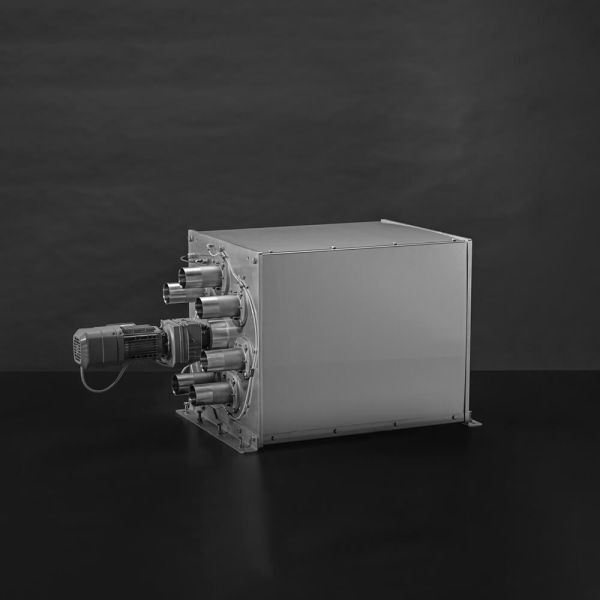

MZC-I

The standard in safety, hygiene and cleanability opens on one side

Meet the MZC-I, our top-level range of rotary valves that sets the standard in the field of safety, hygiene, and cleanability.

Today and in the future. Extreme durability and efficiency, Combined with ease of cleaning, make the MZC-I the reliable core of your production processes.

Maximize your output while cutting time and costs for maintenance and thorough cleaning. MZC-I The all-purpose rotary valve with a compact design.

MZC-II

The standard in safety, hygiene and cleanability opens on two sides for easy accessibility

Meet the MZC-II, our top-level range of rotary valve that sets the standard in the field of safety, hygiene, and cleanability.

Today and in the future. Extreme durability and efficiency, Combined with ease of cleaning,

Make the MZC-II the reliable core of your production processes. Maximize your output while cutting time and costs for maintenance and thorough cleaning.

MZC-II The ultimate rotary valve that meets the highest hygiene requirements.

MALD/MLD

Ideal for vacuum conveying, bulk bag unloading, cyclone applications, and general-purpose use

The MALD and MLD medium-duty rotary valves offer exceptional value and versatility for various applications.

Ideal for vacuum conveying, big bag unloading,

Cyclone applications, and general purposes, Both rotary valves are distinguished by their simple construction

and direct drive. Using the AL rotary valve body with two round flanges, The MALD rotary valve is optimal for powder handling. In contrast, The MLD rotary valve features an ML rotary valve body with larger round and square flanges, enhancing its efficiency with free-flowing products and facilitating transitions between different connections.

DL

Dust lock rotary valve designed for filter applications

The DL dust lock is a rotary valve with a dedicated design for filter applications. It can be used with dust filters, cyclones,

product separators, and dosing systems.

The universal flanges on both sides of the rotary valve are used for round or square connections. This application is much more sensitive to dust explosions; therefore, we have ATEX-certified this valve for equipment or protective systems (explosion barriers).

Diverter Valves

Diverter valves are designed to direct material flow, enabling system flexibility, supporting multiple production lines, and facilitating cleaning and maintenance procedures.

PTD plug diverter valve

Especially designed to route powders and pellets in pneumatic

conveying systems with minimum degradation.

The PTD plug diverter valve is especially designed to route powders and pellets in pneumatic conveying systems with minimum degradation. Precision machining, proper sealing, and obstruction-free internal geometry guarantee a smooth passage of your product. The user-friendly, Foolproof design enables quick on-site internal examination, servicing,

and – when necessary – replacement of seals. The PTD design features no moving parts on the outside and complies with all current guidelines regarding safety in the workplace.

SPTD plug diverter valve

Universal diverter valve for diverting only

The SPTD single pipe plug diverter valve is specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. Precision machining, proper sealing, and an obstruction-free internal geometry

guarantee a smooth passage of the product. The user-friendly,

Foolproof design enables quick on-site internal examination, cleaning and,

SPTDS plug diverter valve

Plug type diverter valve

The SPTDS single pipe plug diverter valve is specially designed to route powders and pellets with minimum degradation in pneumatic conveying systems. Precision machining, proper sealing, and an obstruction-free internal geometry

guarantee a smooth passage of the product. The user-friendly, foolproof design enables quick on-site internal examination, cleaning and, when necessary, replacement of seals. The design of the SPTDS plug diverter valve complies with all current workplace safety legislations. As such, the exterior of this diverter valve is free of moving parts.

GPD plug diverter valve

Two-way, demountable gravity diverter valve ideal for system installations that require frequent cleaning with minimum downtime.

The GPD is a two-way, demountable gravity diverter valve and is ideal for system installations that require frequent cleaning with minimum downtime. Design allows fast disassembly in installed location and easy access to all product-contact surfaces. Material flow through the valve is unrestricted with no ledges or dead spots. The diverters are manufactured in a range of finish options, including sanitary specification. The GPD range also includes USDA Dairy Accepted models. The GPD diverts gravity fed material to either of two lines by a rotating blade that swings through 120° to fully close off the unused port. This is done with extremely close, machined tolerances between rotating blades and body. The GPD is available in 4 sizes: 150, 200, 250 and 300.

2-TDV tube diverter valve

The 2-TDV is a compact diverter valve for pneumatically conveyed powders or pellets. It facilitates material transport to/from two locations.

The 2-TDV is a compact diverter valve for pneumatically conveyed powders or pellets. It facilitates material transport to/from two locations. The 2-TDV ensures precise tube positioning and offers easy disassembly for out-of-place cleaning (COP). Alternatively, in-place cleaning (CIP) is achievable through line purging with cleaning liquid, without diverter valve removal. Complete removal is necessary only for thorough cleaning. This flexibility allows the customization of cleaning methods to fit specific processes. Versions meeting stringent hygienic standards, including USDA Dairy acceptance, are available for specialized applications.

BTD ball type diverter

Well-suited for high-pressure and high-temperature settings.

The BTD ball-type diverter valve, adept at handling abrasive products, Is well-suited for high-pressure and high-temperature settings, Commonly found in thermoelectric power plants (handling coal and fuel oil ash),

Incinerators, foundries, and cement, glass, chemical, and other industries. Versatile in function, it facilitates both

diverging and converging of materials. In diverging applications, the product itself acts as the wear surface. For converging, its impact area is significantly reinforced. Constructed from robust ductile spheroidal cast iron, the BTD is designed for durability and efficiency.

3-TDV tube diverter valve

The 3-TDV diverter valve expertly handles the pneumatic conveyance of powder or pellet materials to/from three destinations.

Engineered for precision, the 3-TDV diverter valve expertly handles the pneumatic conveyance of powder or pellet

materials to/from three destinations. Its compact design incorporates an extra line cylinder, ensuring accuracy in tube positioning. The 3-TDV diverter valve ensures precise tube positioning

and offer easy disassembly for out-of-place cleaning (COP).

M-TDV tube diverter valve

Space-saving multiport tube diverter valve with two-way flows to multiple destinations.

This hygienic, USDA-accepted, and space-saving multiport tube diverter valve ensures optimal product quality. It efficiently handles the pneumatic transport of powders and pellets, with two-way flows to multiple destinations. With flexible mounting, the M-TDV boasts a geared motor and encoder. It offers precise alignment

of your conveyor lines, optimal speed, minimal pressure loss ,And negligible product degradation. Available in sizes from 40 to 150 mm, with 4 up to 14 ports, the M-TDV features a pre-programmed controller with an integrated PLC (compatible with input from your PLC).

FDV flap diverter valve

Characterized by its compact form, simple construction and optimal sealing.

The FDV flap-type diverter valves are designed to divert

powders and pellets in pneumatic conveying systems.

The FDV is available in two versions: the FDV-F type with flange

ends and the FDV-P type with pipe ends. Both versions are available in aluminum,

cast iron, and stainless steel. The FDV has three operating modes:

a pneumatic actuator, an electrical actuator, and manual operation.